Cold Rooms are an indispensable and crucial link in the food supply chain, pharmaceutical warehousing, and chemical raw material management. They are not merely simple cold storage spaces, but rather the infrastructure that enables long-term product preservation through precise temperature control technology. So, what exactly is a Cold Room?

A Cold Room is a sealed storage space that uses a professional refrigeration system to precisely and stably maintain its internal temperature above freezing (typically between 0 and 15 degrees Celsius, most commonly between 2 and 8 degrees Celsius).

The core value of a Cold Room lies in its unique preservation capabilities, primarily manifested in the following aspects:

- Inhibiting Microbial Activity: The low-temperature environment significantly slows down the growth and reproduction of bacteria, mold, and other microorganisms, thereby delaying food spoilage.

- Slowing Down Physiological Metabolism: For fresh produce such as fruits and vegetables, Cold Rooms effectively reduce their respiration, slowing down their ripening and aging processes, and enabling long-term low-temperature storage.

- Precise Temperature Control: Professional Cold Rooms are equipped with high-precision temperature control and monitoring systems to ensure a constant environment, which is crucial for the storage of biological agents and certain pharmaceuticals.

Content

Differences between Cold Storage and Freezer Rooms: The Key Lies in Temperature Boundaries

Although both are cold storage or low-temperature storage facilities, Cold Rooms and freezers have fundamentally different functional objectives and temperature control ranges. Understanding these differences is key to choosing the right refrigeration system:

- Different Temperature Ranges: Cold Rooms operate at temperatures always above the freezing point of water, i.e., above 0 degrees Celsius, for the purpose of preservation, not freezing. Freezer rooms typically maintain temperatures at -18 degrees Celsius or even lower to achieve deep freezing.

- Different Storage Purposes: Cold Rooms are suitable for short- to medium-term low-temperature storage, mainly for storing fresh fruits and vegetables, dairy products, beverages, and pharmaceuticals requiring refrigeration. Freezer rooms are used for meat, seafood, and frozen foods that require long-term, fully frozen storage.

- Different Effects on the State of Goods: Cold Rooms maintain the liquid state or original state of goods to preserve their freshness. The freezer compartment achieves ultra-long-term preservation by condensing the internal moisture of items into ice.

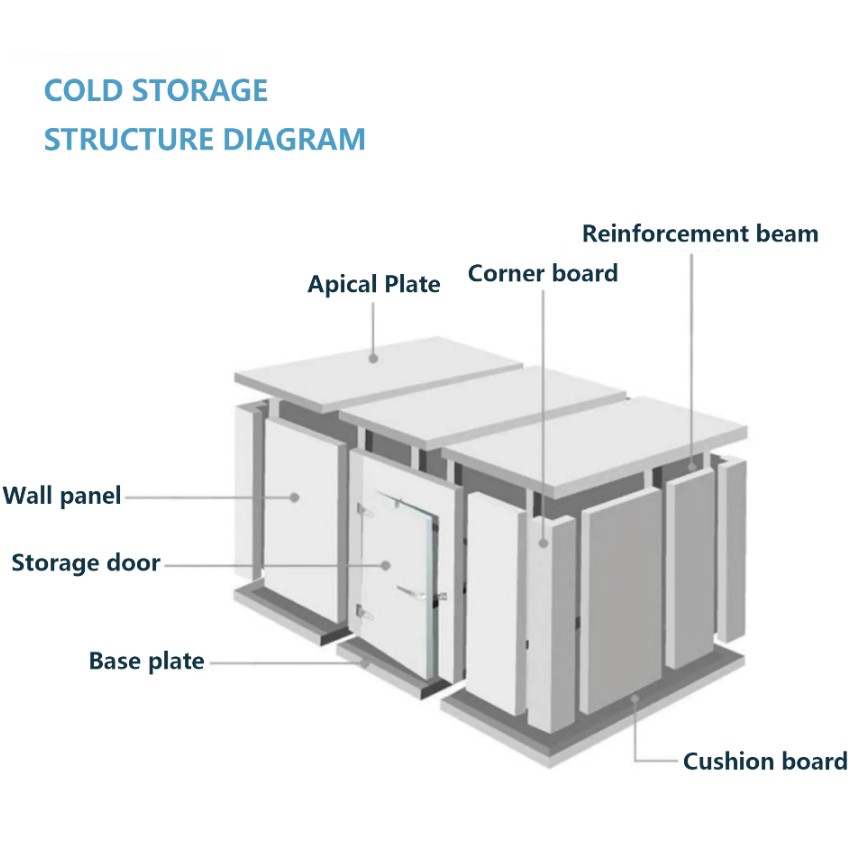

Key Technical Components for Building a Cold Storage Compartment

A high-efficiency, energy-saving cold storage system relies on the coordinated operation of multiple specialized components to ensure a stable low-temperature storage environment:

- Refrigeration System: Including the compressor, condenser, and evaporator (air cooler), this is the foundation for providing the cold source and achieving temperature control. Its design must be matched to the volume and heat load of the cold storage compartment.

- Insulation Structure: High-performance insulation materials (such as polyurethane insulation panels) constitute the walls, floor, and ceiling of the cold storage compartment, maximizing the insulation against external heat and ensuring minimal energy consumption.

- Temperature Control and Monitoring System: Advanced electronic controllers and sensors are used to monitor and precisely regulate the temperature and humidity within the cold storage compartment in real time, ensuring that the stringent standards required for preservation are met.

English

English Español

Español عربى

عربى русский

русский