In a refrigeration system, the condenser is an indispensable and crucial component. Its main function is to cool the refrigerant, compressed from a high-temperature, high-pressure gas in the compressor, into a liquid state, providing the power for system circulation. The condenser not only affects the efficiency of the refrigeration system but also directly relates to energy consumption and equipment lifespan. In modern air conditioners, refrigerators, and industrial refrigeration equipment, the selection and maintenance of the condenser are of paramount importance.

Content

Basic Working Principle of a Condenser

The condenser transfers heat released by the high-temperature refrigerant to the surrounding medium (such as air or water) through heat transfer. In this process, the refrigerant changes from a gaseous state to a liquid state, completing the heat transfer. For example, in household air conditioners, the condenser typically contacts the air through fins, transferring the heat from the refrigerant to the outdoor air. In industrial refrigeration systems, the condenser may use water cooling, using circulating cooling water to remove heat.

Scientific data shows that the heat exchange efficiency of the condenser directly affects the energy consumption of the refrigeration system. For example, for every 5% decrease in condenser efficiency, system energy consumption may increase by 3% to 5%. Therefore, selecting a high-efficiency condenser not only improves cooling performance but also saves operating costs.

Condenser Types and Applications

Condensers are mainly classified into three categories: air-cooled condensers, water-cooled condensers, and evaporative condensers.

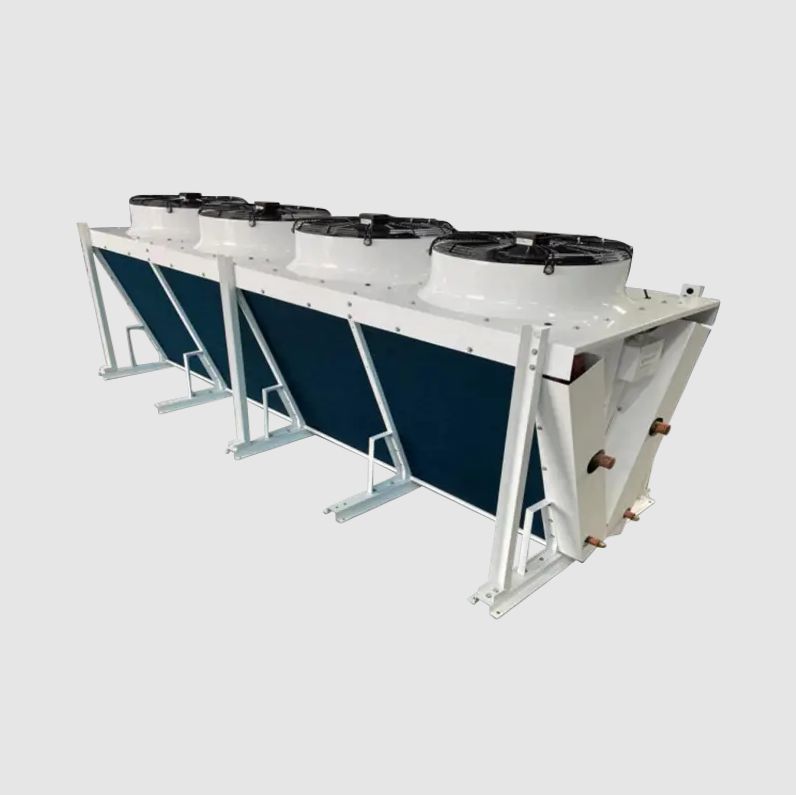

Air-cooled condensers: Utilize airflow to remove heat from the refrigerant. They have a simple structure and are suitable for residential and small commercial air conditioning. Typical cooling capacity is 1-10 kW.

Water-cooled condensers: Cool the refrigerant through water circulation. They have high heat exchange efficiency and are suitable for large industrial refrigeration systems and central air conditioning. Cooling capacity can reach hundreds of kilowatts or even megawatts.

Evaporative condensers: Combine the principle of water evaporation for cooling. They are suitable for high-temperature and high-humidity environments and have a high energy efficiency ratio, but maintenance costs are relatively high.

Choosing the appropriate condenser type allows for optimization based on the scale of the refrigeration system, environmental conditions, and energy consumption budget. For example, a large supermarket that replaced air-cooled condensers with water-cooled condensers saw an annual electricity cost reduction of approximately 12%.

The Importance of Condenser Maintenance

During long-term operation, condensers are prone to dust accumulation, scaling, or corrosion, directly leading to a decrease in heat exchange efficiency. For example, if dust accumulation on the fins of an air conditioner condenser exceeds 5 mm, the cooling efficiency may decrease by 10% to 15%. Regular cleaning and checking of refrigerant pressure and water quality are key measures to ensure condenser performance.

Furthermore, modern condensers can improve heat transfer efficiency by optimizing fin design, increasing fan efficiency, or using nano-coating technology. Company data shows that upgraded high-efficiency condensers can reduce energy consumption by more than 15% while extending equipment life by 3 to 5 years.

How to Choose a High-Efficiency Condenser

When purchasing a condenser, pay attention to the following key indicators:

Heat exchange area: The larger the area, the higher the heat exchange efficiency.

Corrosion resistance: Especially for water-cooled condensers, copper tubing or stainless steel should be used to prevent scaling and corrosion.

Fan or pump performance: Directly affects the heat transfer speed of the condenser.

Energy efficiency ratio (EER/SEER): Measures the energy utilization rate of the entire refrigeration system; high-efficiency condensers can significantly reduce operating costs.

For example, an air-cooled condenser using a high-density aluminum fin design achieves a 12% higher cooling efficiency than traditional condensers, reducing annual energy consumption by approximately 500 kWh.

The condenser plays a crucial role in a refrigeration system, and its performance directly impacts cooling efficiency and energy consumption. Whether for residential air conditioners or large industrial refrigeration equipment, understanding condenser types, operating principles, and maintenance methods is essential for improving system performance and reducing operating costs. Selecting a high-efficiency, durable condenser and performing regular maintenance are key to ensuring the long-term stable operation of the refrigeration system.

English

English Español

Español عربى

عربى русский

русский